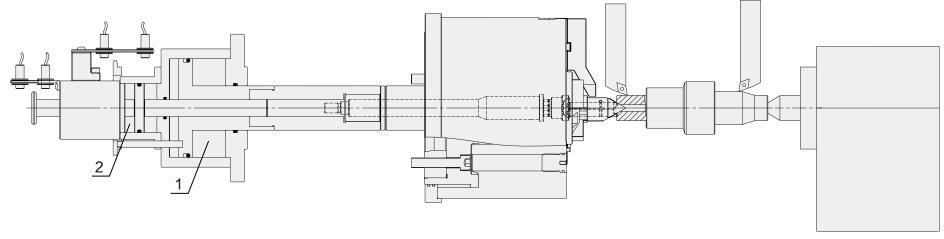

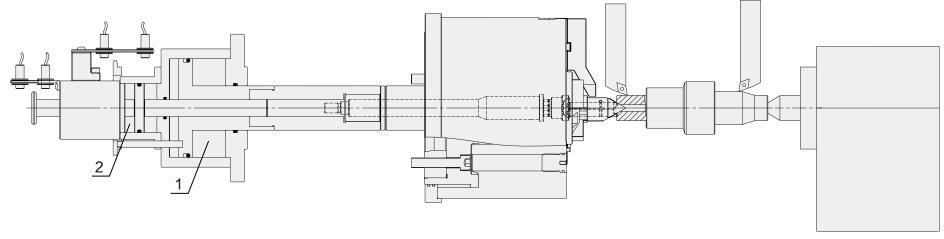

SF type end face driven fixed tip shafting processing chuck

(end face drive shall be designed and manufactured according to the work piece)

positioning by central hole at axial direction

Fixed tip can guarantee highest concentricity

Drive pin is driven by piston 2 of double piston cylinder,Jacking into work piece end face (piston 1 is used for chuck drive)

End face drive clamping/ the loose position can be monitored through proximityswitch/LPS

The highest accuracy - without adjustment

The tip can be customized according to the size of the work piece during ordering

Shaft Processing Chuck With Fixed Tip End Face Driving

Double Piston Oil Cylinder Drive Model: RDN

Center Tip Positioning At Axial Direction

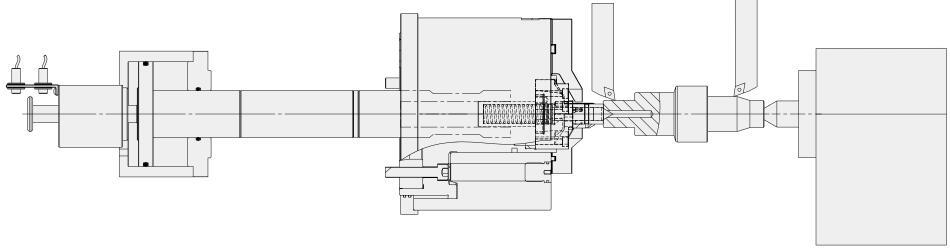

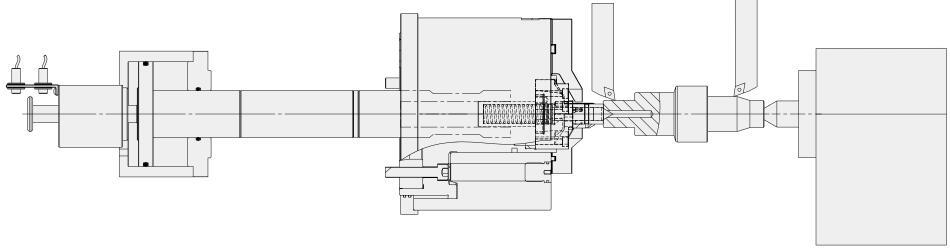

SF Type End Face Driven Spring Tip

(end face drive shall be designed and manufactured according to the work piece)

Positioning by end face at axial direction

The work piece is pushed to drive pin and spring tip by tailstock thrust Drive pin jacking into the work piece end face

Keep the position of spring tip and work piece shaft through a special built-in locking mechanism

Highest accuracy - without adjustment

The tip can be customized according to the size of the work piece during ordering

End Face Driven Spring Tip For Shaft Processing Of Chuck

RS-N Large Stroke Oil Cylinder

Positioning By Work Piece End Face At Axial Direction

Performance parameters

| BDF-AUTOCHACK Model |

| SF-215 | SF-260 | SF-325 | SF-460 |

| Installation form |

| A06 | A06 | A08 | A08 | A11 | A11 | A15 |

| Chuck outer diameter | A | 220 | 260 | 325 | 460 |

| Chuck height | B | 176 | 235 | 213 | 285 | 251 | 344 | 309 |

| C | 230 | 270 | 335 | 470 |

| D | 106.375 | 106.375 | 139.719 | 139.719 | 196.869 | 196.869 | 285.775 |

| E | 133.4 | 133.4 | 171.4 | 171.4 | 235 | 235 | 330.2 |

| G | M34X1.5 | M33x1.5 | M45x1.5 | M85x2 |

| G1 | M12 | M16 | M16 | M56 |

| G2 | M12 | M12 | M16 | M16 | M20 | M20 | M24 |

| G3 | M10 | M12 | M12 | M16 |

| H | 42 | 54 | 70 | 110 |

pull rod drive distance

minimum/maximum | L | 55/40 | 96.5/81.5 | 121.5/106.5 | 106/91 | 140/125 | 119/104 | 154/139 |

pull rod drive distance

minimum/maximum | M | 44M | 96.5/26.5 | 121.5/51.5 | 106/26.8 | 140/60.8 | 119/24.4 | 154/56.5 |

| N | 30 | 42 | 42 | 42 |

| P | 15.5 | 18 | 21 | 24 | 26 | 26 | 34 |

| R | 30 | 45 | 50 | 50 |

| S | 15 | 16.5 | 16.5 | 56.5 |

| U | 10 | 15 | 15 | 15 |

| Axial movement/chuck body | Z | 40 | 53 | 58 | 68 |

| Width*depth | a | 16*3 | 18*4 | 18*4 | 22*4 |

| b | 32 | 36 | 45 | 52 |

| c | 35 | 40 | 40 | 50 |

| d | 56.5 | 75 | 96.5 | 150.5 |

| e | 4 | 4 | 4 | 4 |

| f | 10 | 12 | 12 | 16 |

| Max. claw stroke (diameter) | mm | 5.3 | 5.8 | 7.6 | 9 |

| Highest rotating speed | r.p.m | 3000 | 2500 | 2000 | 1500 |

| The biggest push & pull force | KN | 30 | 50 | 75 | 100 |

| Maximum clamping force | KN | 60 | 100 | 150 | 200 |

| Weight | KG | 40 | 75 | 70 | 140 | 127 | 364 | 336 |

The above data are the standard parameters, personalized customized solutions can be provided according to customer's requirement.

Türkçe

English

Русский

繁體中文

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Māori

नेपाली

Oʻzbekcha

latviešu

Беларуская мова

Български

íslenska

Lietuvių