Soft jaws are often used when machining delicate or thin-walled components that could be damaged by traditional hard jaws. The soft material of the jaw helps to distribute clamping forces evenly and reduces the risk of distortion or damage to the workpiece. Soft jaws are also commonly used when clamping irregularly shaped or contoured parts.

On the other hand, hard jaws are made from a harder material. Hard jaws are used for clamping and securing workpieces that require higher clamping forces or more rigid support. They are typically used for machining solid, robust components that can withstand the pressure exerted by the jaws.

Size parameter

| Spec. | S-1 | S-2 | S-3 | S-4 | S-5 | S-6 | S-7 | S-8 | S-9 | S-10 | Comb pitch | Weight Kg |

| 110 | 52 | 22 | 22 | 8 | 4 | 16 | 14 | 15 | 6.5 | 11 | 1.0x60° | 0.4 |

| 4' | 52 | 23 | 23 | 10 | 5 | 10 | 14 | 13 | 9 | 13.5 | 1.5x60° | 0.5 |

| 5' | 62 | 25 | 30 | 10 | 5 | 10 | 14 | 18 | 9 | 13.5 | 1.5x60° | 0.8 |

| 6' | 73 | 31 | 36 | 12 | 5 | 15 | 20 | 24 | 11 | 17 | 1.5x60° | 1.5 |

| 8' | 95 | 35 | 37 | 14 | 5 | 24 | 25 | 22 | 13 | 19 | 1.5x60° | 2.4 |

| 10' | 110 | 40 | 42 | 16 | 5 | 30 | 30 | 27 | 13 | 19 | 1.5x60° | 3.8 |

| 12P' | 130 | 50 | 50 | 18 | 5 | 40 | 30 | 33 | 15 | 23 | 1.5x60° | 6.3 |

| 12H' | 130 | 50 | 50 | 21 | 5 | 40 | 30 | 33 | 17 | 26 | 1.5x60° | 6.6 |

| 15P' | 165 | 62 | 62 | 25.5 | 8 | 37 | 43 | 38 | 21 | 32 | 1.5x60° | 12.6 |

| 15H' | 165 | 62 | 62 | 22 | 8 | 37 | 43 | 38 | 21 | 32 | 1.5x60° | 12.5 |

| 21' | 180 | 65 | 70 | 25 | 9 | 40 | 60 | 45 | 21 | 32 | 3.0x60° | 15.8 |

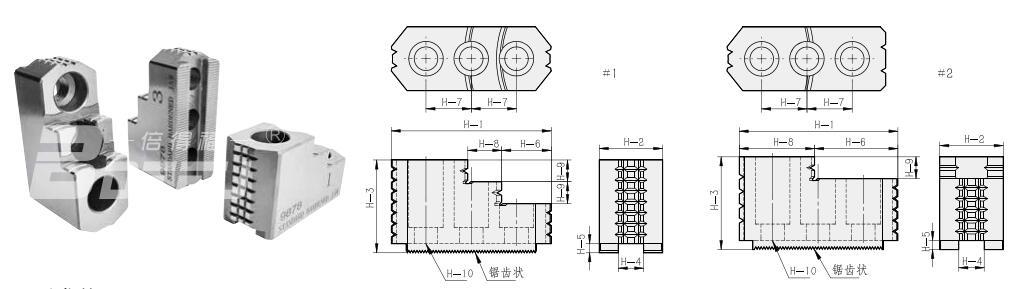

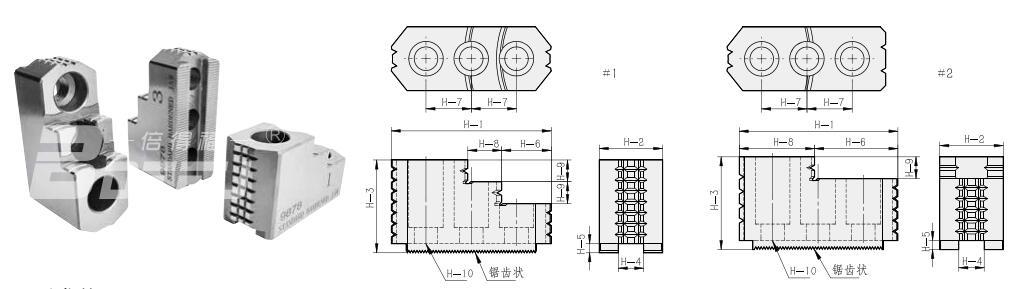

Size parameter

| Spec. | H-1 | H-2 | H-3 | H-4 | H-5 | H-6 | H-7 | H-8 | H-9 | H-0 | Serration Pitch | Weight | Reterence Drawing |

| HJ-04 | 53 | 23 | 28 | 10 | 4 | 29 | 14 | 24 | 10 | M8X1.25P | 1.5X60° | 0.4 | Fig.2 |

| HJ-05 | 53 | 23 | 28 | 10 | 4 | 29 | 14 | 24 | 10 | M8X1.25P | 1.5x60° | 0.4 | Fig.2 |

| HJ-06 | 67 | 31 | 36 | 12 | 5 | 39 | 20 | 28 | 12 | M10X1.5P | 1.5X60° | 0.95 | Fig.2 |

| HJ-08 | 87 | 35 | 51 | 14 | 5 | 29.5 | 25 | 18 | 12 | M12X1.75P | 1.5X60° | 1.9 | Fig.1 |

| HJ-10 | 101 | 40 | 54 | 16 | 5 | 45.5 | 30 | 18 | 13 | M12X1.75P | 1.5X60° | 2.8 | Fig.1 |

| HJ-12 | 108 | 50 | 67 | 21(18) | 4(5) | 49 | 30 | 20 | 16 | M16X2P(M14X2P) | 1.5X60° | 3.5 | Fig.1 |

| HJ-15 | 143 | 62 | 86 | 22(25.5) | 8(5) | 55 | 43 | 38 | 20 | M20X2.5P | 1.5x60° | 9.5 | Fig.1 |

| HJ-18 | 143 | 62 | 86 | 22(25.5) | 8(5) | 55 | 43 | 38 | 20 | M20X2.5P | 1.5X60° | 9.5 | Fig.1 |

| HJ-21 | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20X2.5P | 3x60° | 15.3 | Fig.2 |

| HJ-24 | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20X2.5P | 3X60° | 15.3 | Fig.2 |

| HJ-32 | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20X2.5P | 3X60° | 15.3 | Fig.2 |

| HJ-40 | 159.5 | 80 | 90 | 25 | 9 | 97.5 | 50 | 62 | 40 | M20X2.5P | 3x60° | 15.3 | Fig.2 |

The above data are the standard parameters, personalized customized solutions can be provided according to customer's requirement.

Türkçe

English

Русский

繁體中文

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Māori

नेपाली

Oʻzbekcha

latviešu

Беларуская мова

Български

íslenska

Lietuvių