The flange usually has a circular shape with bolt holes around its perimeter to allow for easy and secure attachment to the chuck and the pneumatic system. The bolt holes are typically aligned with corresponding holes on the chuck and the pneumatic system to ensure a proper fit and alignment.

The pneumatic chuck connection flange is designed to provide a tight and secure connection between the chuck and the pneumatic system, allowing for efficient and reliable operation of the chuck. It plays a critical role in maintaining the stability and accuracy of the chuck during machining or other operations.

Overall, the pneumatic chuck connection flange is an essential component in pneumatic systems that use chucks, providing a reliable and secure connection between the chuck and the rest of the system.

Size parameter

| Spec. | A | B | C | D | E | F | G | H | I | J |

| KS05-3-A4 | 63.513 | 135 | 95 | 4.5 | 23.5 | 17 | 115 | 82.6 | 3-M8 | 3-M10X20 |

| KS06-3-A5 | 82.563 | 172 | 154 | 4.5 | 28.5 | 22 | 154 | 104.8 | 3-M8 | 6-M10X30 |

| KS08-3-A6 | 106.375 | 210 | 165 | 4.5 | 28.5 | 22 | 186 | 133.4 | 3-M10 | 6-M12X30 |

| KS10-3-A8 | 139.719 | 254 | 206 | 4.5 | 33.5 | 27 | 230 | 171.4 | 3-M12 | 6-M16X35 |

| KS12-3-A8 | 139.719 | 315 | 270 | 4.5 | 33.5 | 27 | 290 | 171.4 | 3-M12 | 6-M16X35 |

The above data are the standard parameters, personalized customized solutions can be provided according to customer's requirement.

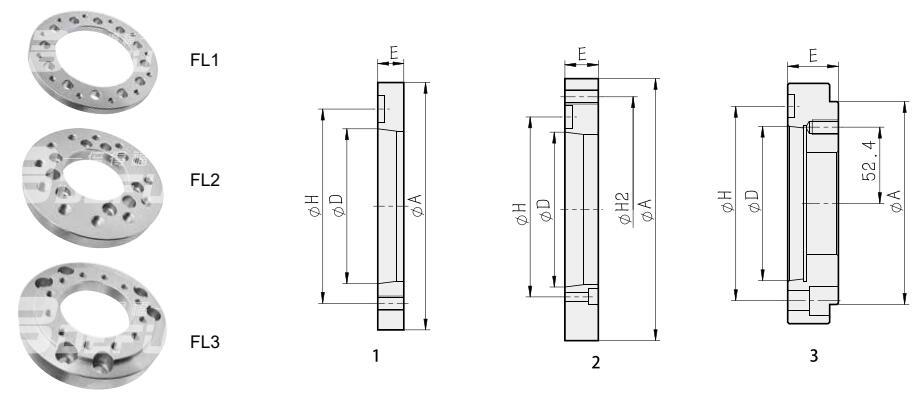

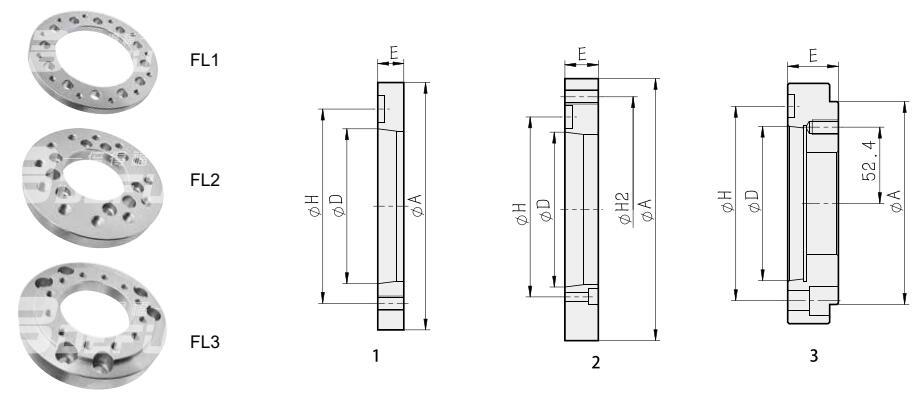

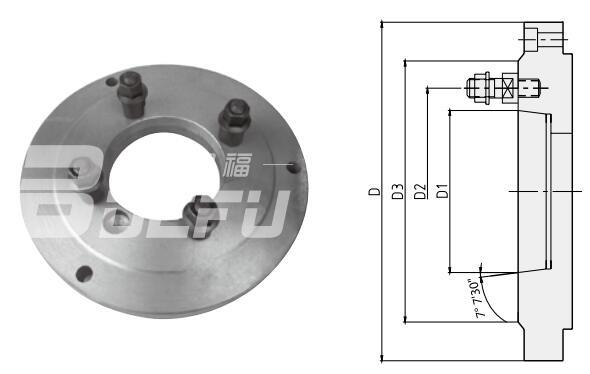

Flange connecting diagram

| Size/Spec. | Nose of Spindle

D | A | H | H2 | E | Reference Drawing |

| 05A24 | A24 | 110 | 82.6 | - | 20 | Fig.1 |

| 06A25 | A25 | 140 | 104.8 | - | 15 | Fig.1 |

| 08A26 | A26 | 170 | 133.4 | - | 17 | Fig.1 |

| 10A28 | A28 | 220 | 171.4 | - | 18 | Fig.1 |

| 12A28 | A28 | 220 | 171.4 | - | 18 | Fig.1 |

| 15A211 | A211 | 300 | 235 | - | 22 | Fig.1 |

| 18A211 | A211 | 300 | 235 | - | 22 | Fig.1 |

| 21A215 | A215 | 380 | 330.2 | - | 27 | Fig.1 |

| 24A220 | A220 | 520 | 463.6 | - | 27 | Fig.1 |

| 32A215 | A215 | 380 | 330.2 | - | 27 | Fig.1 |

| 40A215 | A215 | 380 | 330.2 | - | 27 | Fig.1 |

| 04A24 | A24 | 85 | 82.6 | 70.6 | 40 | Fig.3 |

| 05A25 | A25 | 110 | 104.8 | 82.6 | 45 | Fig.3 |

| 06A24 | A24 | 140 | 82.6 | 104.8 | 20 | Fig.2 |

| 06A26 | A26 | 140 | 133.4 | 104.8 | 40 | Fig.3 |

| 08A25 | A25 | 170 | 104.8 | 133.4 | 24 | Fig.2 |

| 08A28 | A28 | 170 | 171.4 | 133.4 | 45 | Fig.3 |

| 10A26 | A26 | 220 | 133.4 | 171.4 | 28 | Fig.2 |

| 12A26 | A26 | 220 | 133.4 | 171.4 | 28 | Fig.2 |

| 12A211 | A2II | 220 | 235 | 171.4 | 54 | Fig.3 |

| 15A28 | A28 | 300 | 171.4 | 235 | 33 | Fig.2 |

| 18A28 | A28 | 300 | 171.4 | 235 | 33 | Fig.2 |

| 21A28 | A28 | 380 | 171.4 | 330.2 | 41 | Fig.2 |

| 21A211 | A2II | 380 | 235 | 330.2 | 41 | Fig.2 |

| 24A211 | A211 | 520 | 235 | 463.6 | 42 | Fig.2 |

| 24A215 | A215 | 520 | 330.2 | 463.6 | 42 | Fig.2 |

| 32A211 | A211 | 380 | 235 | 330.2 | 41 | Fig.2 |

| 40A211 | A211 | 380 | 235 | 330.2 | 41 | Fig.2 |

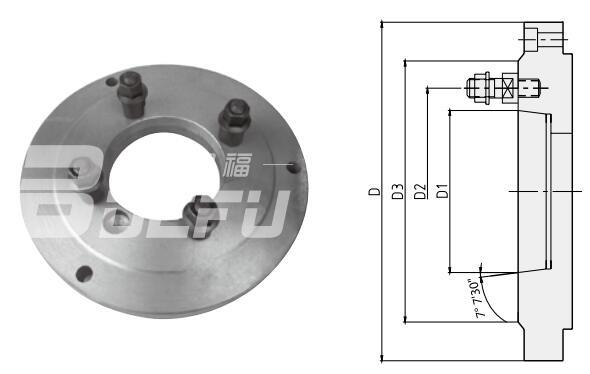

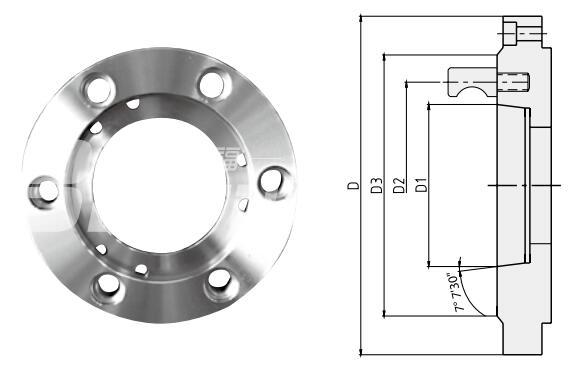

Type C

| No. | 3 | 4 | 5 | 6 | 8 | 11 | 15 |

| D1 | 53.975 | 63.513 | 82.563 | 106.375 | 139.719 | 196.869 | 285.775 |

| D2 | 75 | 85 | 104.78 | 133.35 | 171.45 | 235 | 330.2 |

| D3 | 102 | 112 | 135 | 170 | 220 | 290 | 400 |

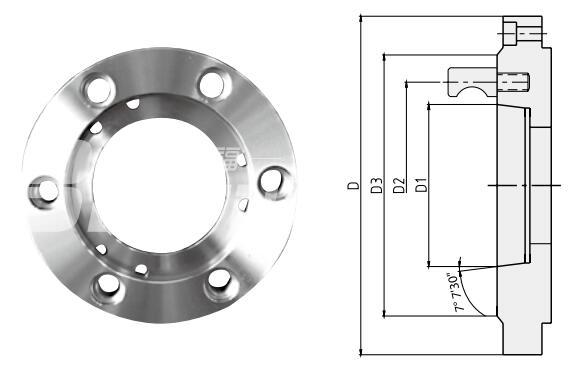

Type D

| No. | 3 | 4 | 5 | 6 | 8 | 11 | 15 |

| D1 | 53.975 | 63.513 | 82.563 | 106.375 | 139.719 | 196.869 | 285.775 |

| D2 | 70.6 | 82.563 | 104.78 | 133.35 | 171.45 | 235 | 330.2 |

| D3 | 92 | 117 | 146 | 181 | 225 | 298 | 403 |

The above data are the standard parameters, personalized customized solutions can be provided according to customer's requirement

Türkçe

English

Русский

繁體中文

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Māori

नेपाली

Oʻzbekcha

latviešu

Беларуская мова

Български

íslenska

Lietuvių