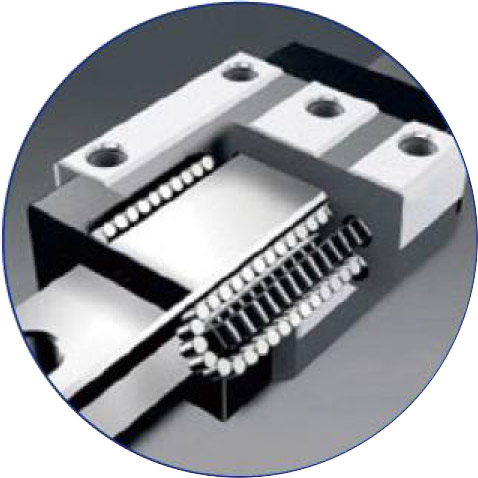

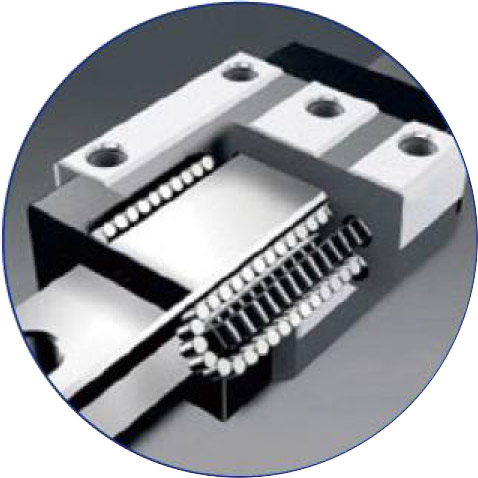

The three axles provided with ultra-high rigid roller rails can bear equal loads in four directions. The roller retainer provided may prevent deviation and realize balanced and stable movement, ensuring the accuracy and stability of the machine tool after long-term operation.

Z-axis has a balance cylinder and a Z-axis balanced power-off energy storage protection system, which is quick and agile. The machine tool may improve the reliability and precision stability and save at least 50% of energy consumption.

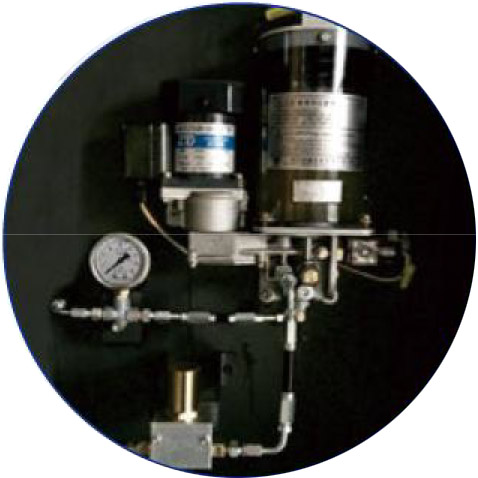

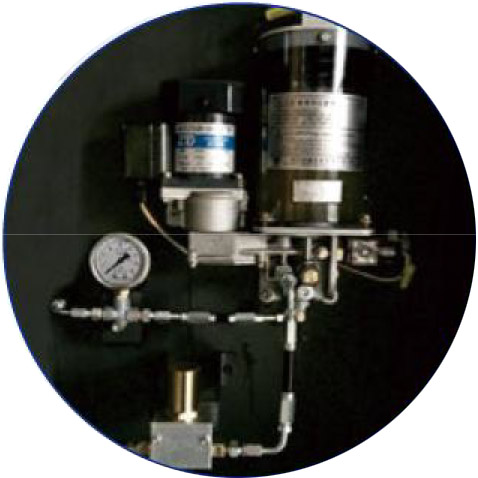

Hydraulic and grease lubrication system consists of filter system, pressure relay pressure protection system, temperature protection alarm and low oil level protection alarm. Air-conditioning oil cooling device of the spindle may control the temperature within the set range and improve the ability and precision stability of the machine tool.

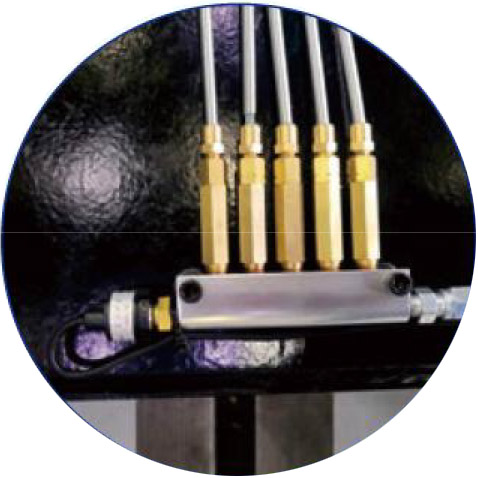

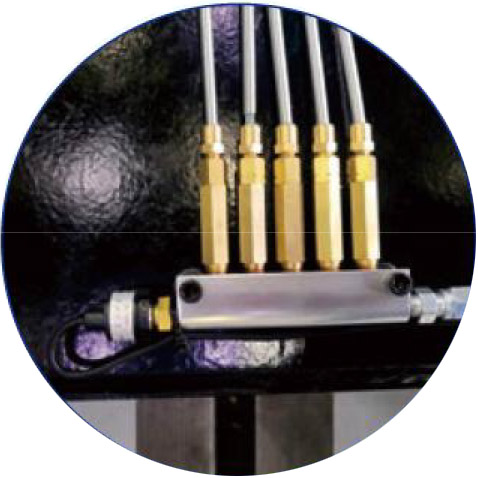

The guide rail lubrication of X-axis, Y-axis and Z-axis motion guide rails are performed by centralized automatic lubrication system with oil shortage safety protection.

The overall lubrication of machine tool is subject to monitoring and control at key positions by the pressure relays.

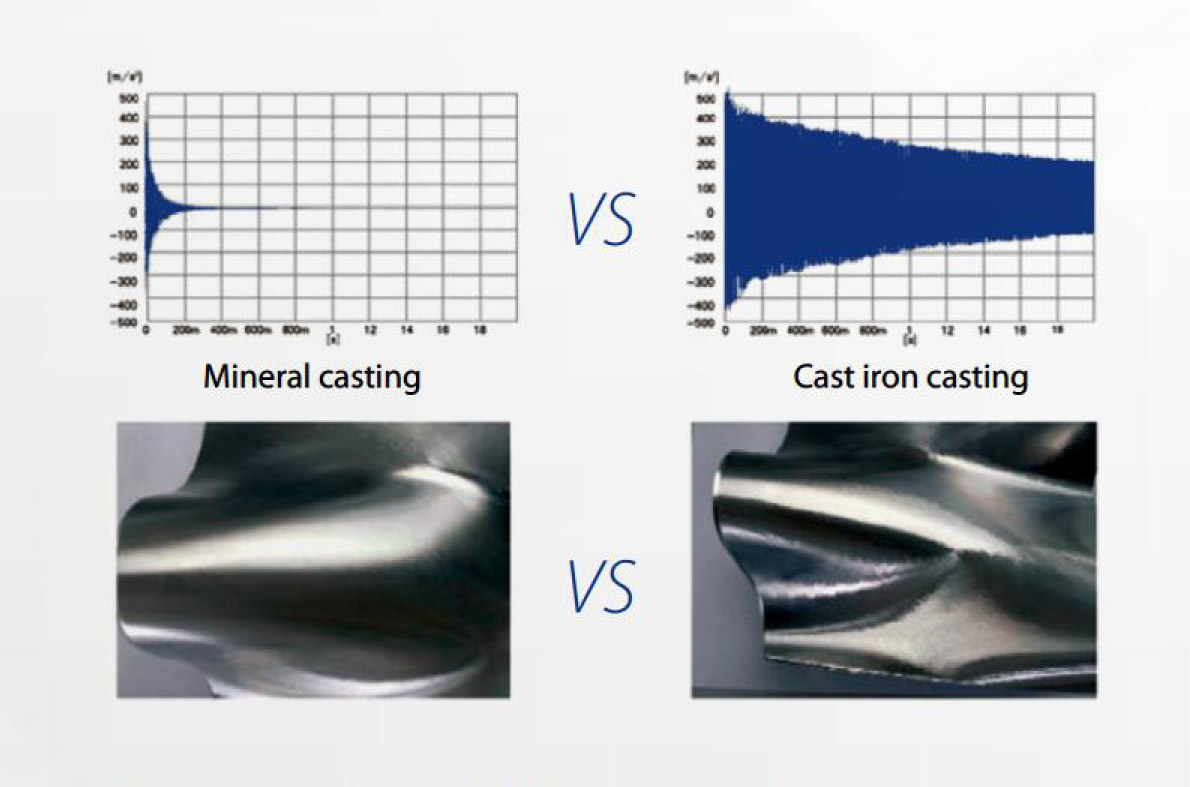

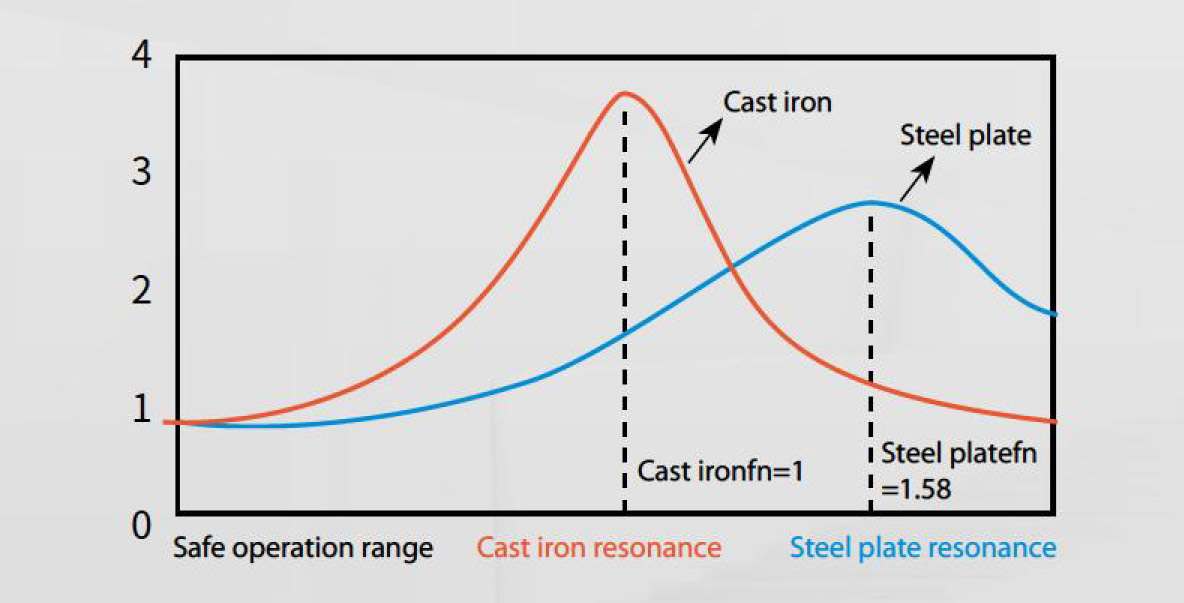

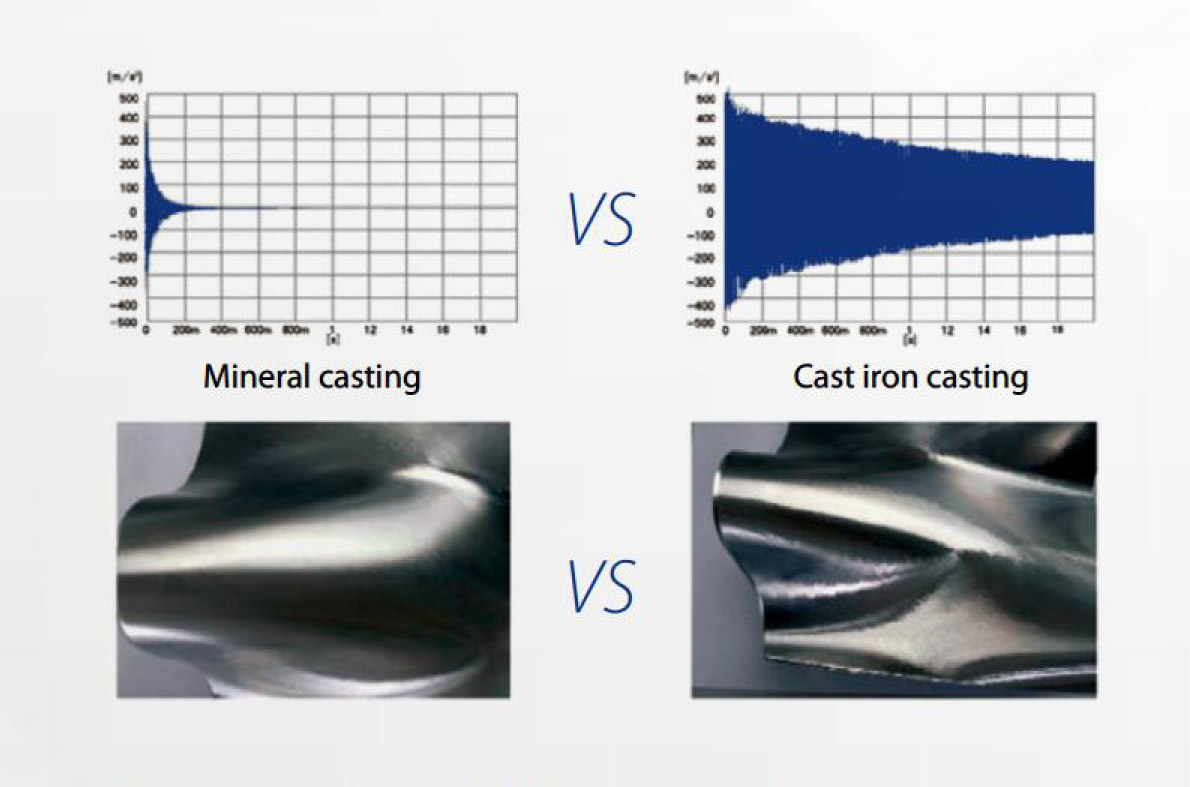

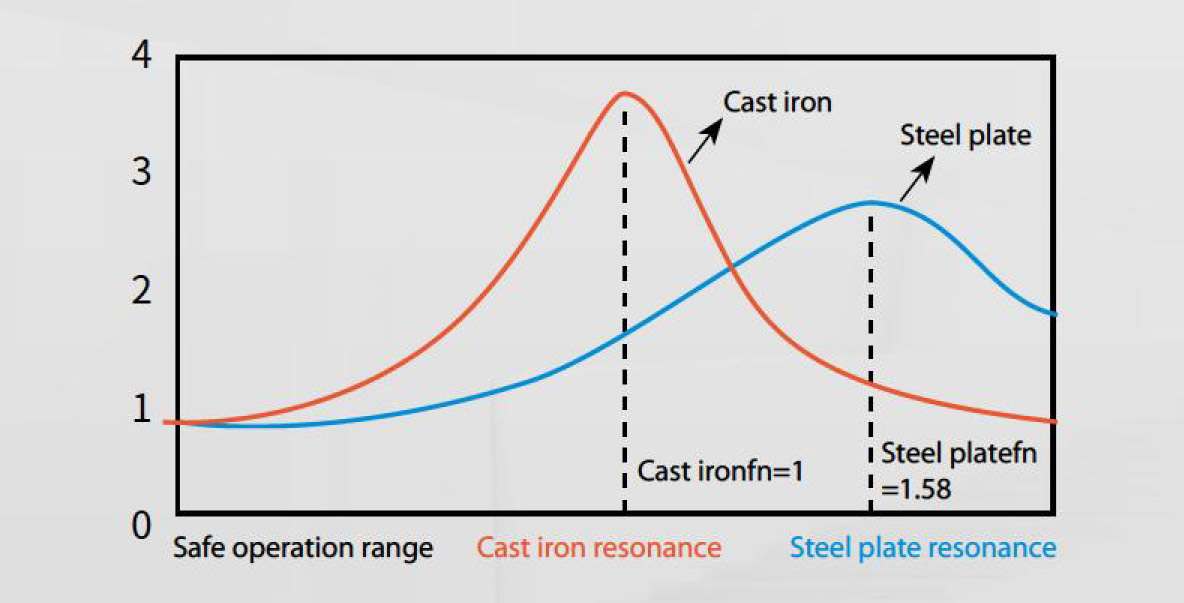

The contrast test of damping automatic vibration response has proven that mineral castings have strong vibration absorption, which is 10 times that of cast iron. Under large dynamic load, the stability of machine tool accuracy is ensured, and the machining quality of workpiece surface is improved by 20%.

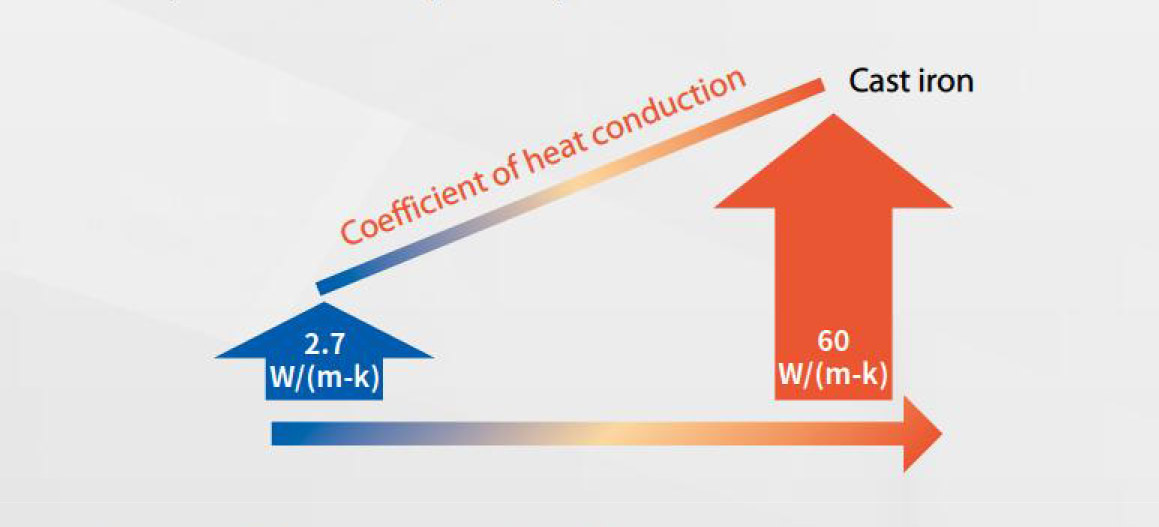

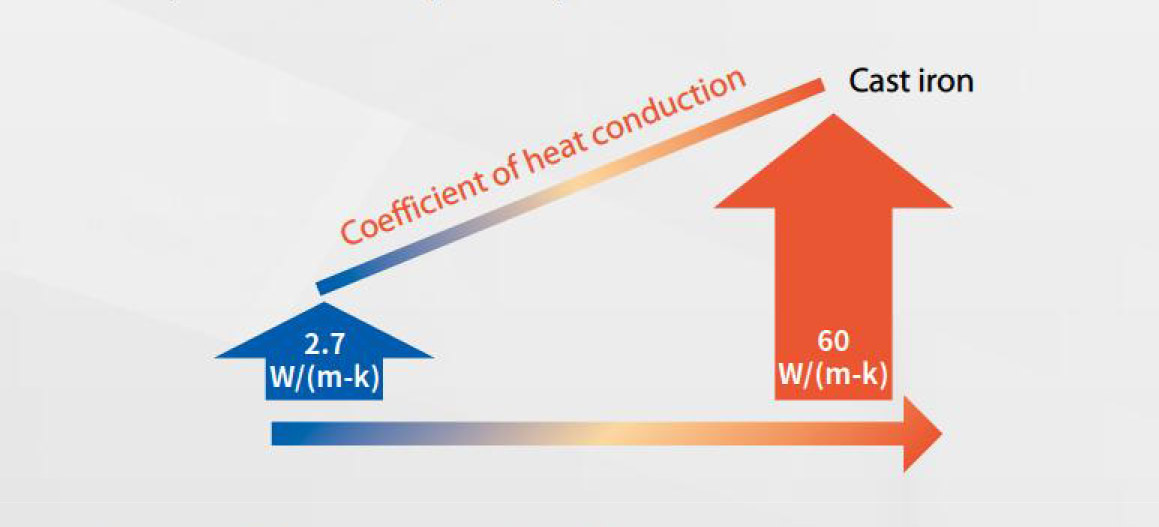

The thermal conductivity is 1/20 of that of cast iron, and the specific heat capacity is 2.1 times of that of cast iron. In the process of parts machining by the machine tool, the thermal influence is the main factor causing the machining dimension deviation. Excellent thermal stability and thermal inertia may effectively control the deformation of the machine tool caused by temperature changes and ensure the stable machining accuracy of the machine tool.

The moving parts are welded by high-strength low-alloy steel. The elastic modulus of moving parts is about 1.4 times that of cast iron, and the overall rigidity of the structure is improved by more than 30%.

On the premise of the same rigidity, the weight of steel weldments is reduced by about 20%~30% compared with iron castings, which effectively reduces the inertia of moving parts and improves the dynamic response by 10%~20%.

Compared with the cast iron material with the same structure, the natural frequency of steel weldments is significantly improved, the possibility of resonance during cutting is reduced, and the cutting stability and machining accuracy are improved.

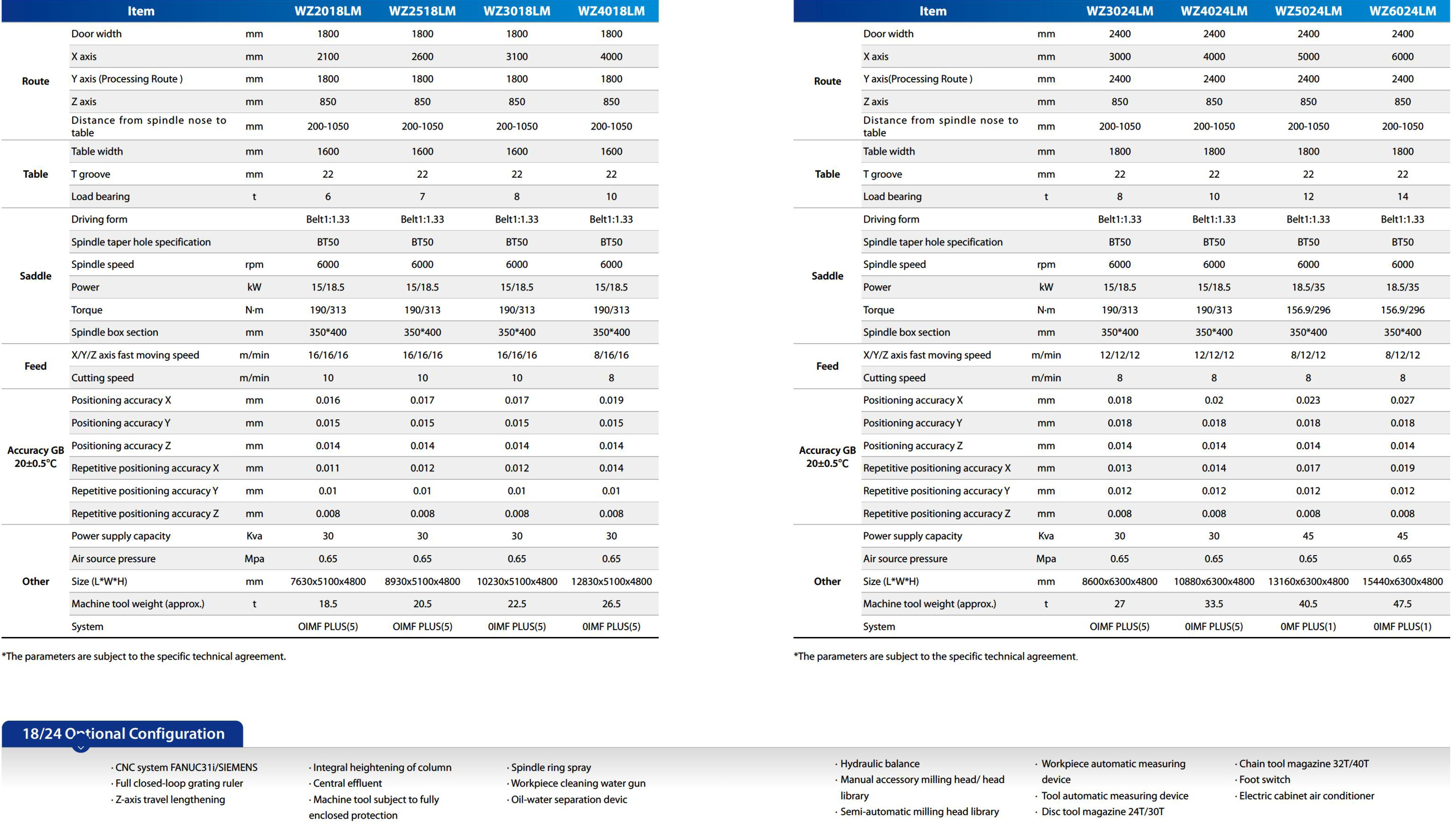

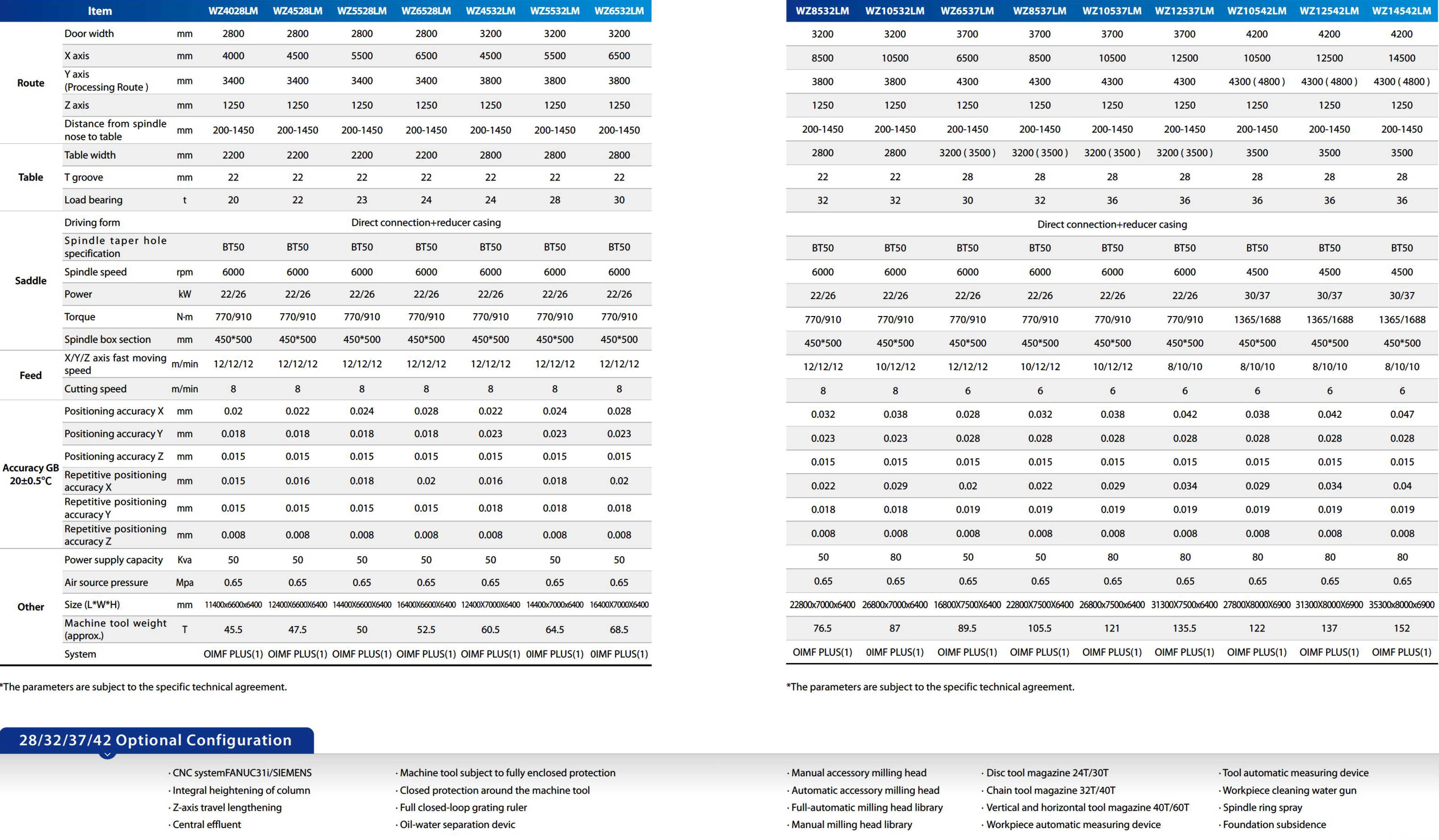

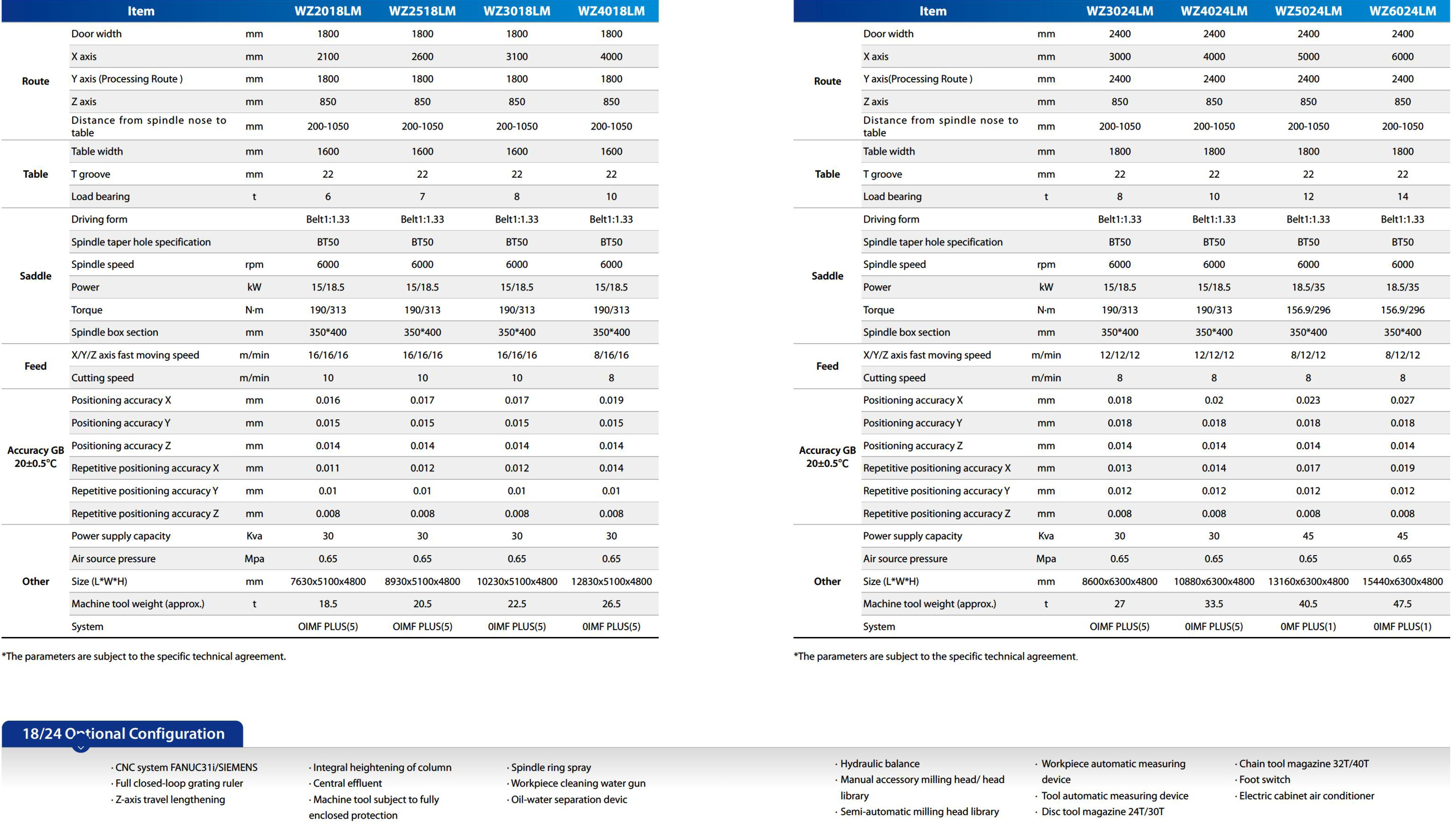

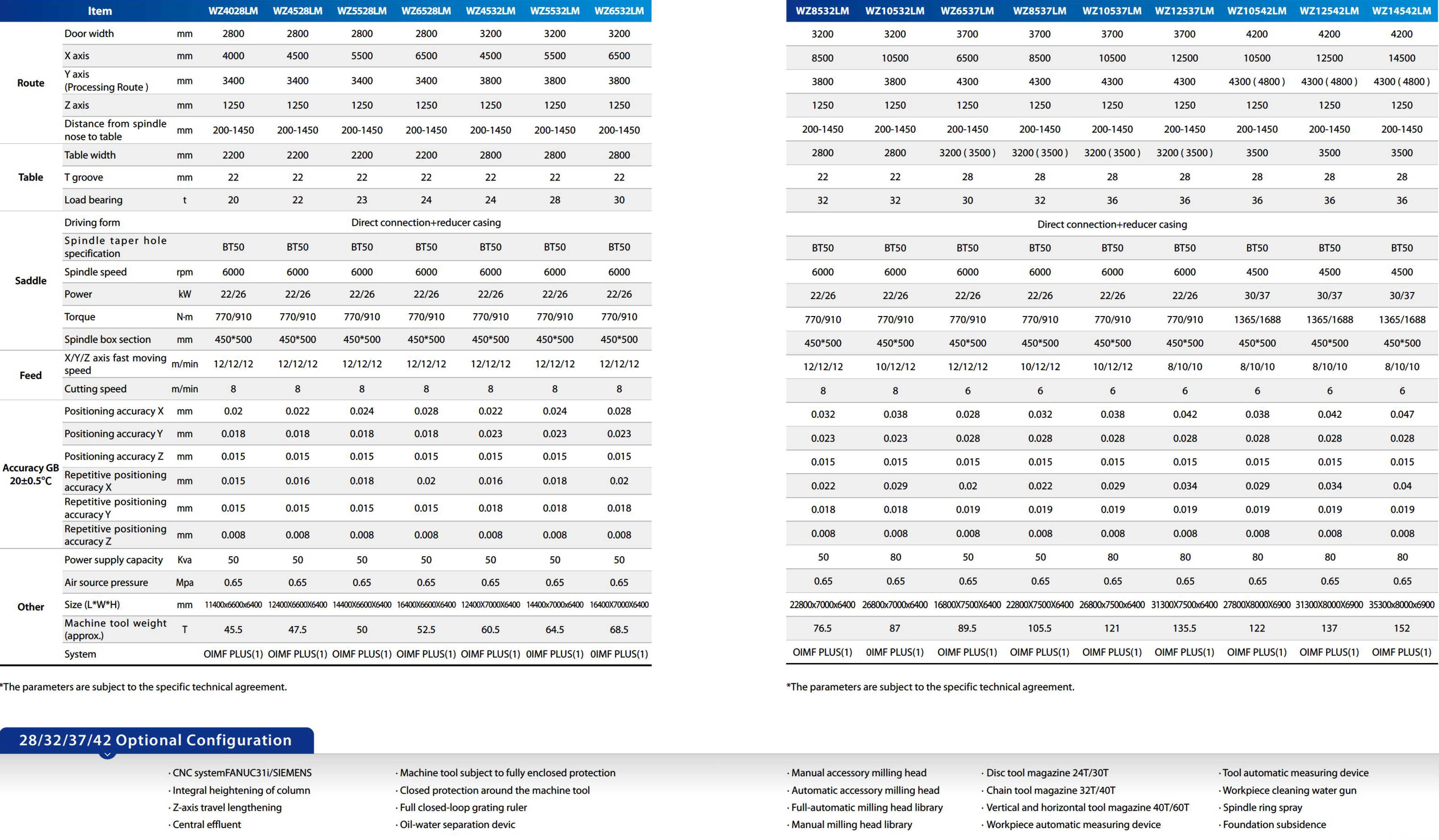

Technical Parameters

Türkçe

English

Русский

繁體中文

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

Dansk

اردو

বাংলা

Hrvatski

Afrikaans

Gaeilge

Māori

नेपाली

Oʻzbekcha

latviešu

Беларуская мова

Български

íslenska

Lietuvių